Gas Spring Installation & Safety

Thank you for purchasing a Dictator Engineering Gas Spring. This guide will help to ensure the longevity of your gas springs.

Gas Spring Installation

- Wherever possible install gas spring in a clean environment away from sources of contamination, dust and dirt.

- Install Gas Springs piston rod downwards. However you must install pull type gas springs piston upwards.

- Where this is not possible please consult Dictator for advice.

- Select mounting brackets and end fittings to ensure that the gas springs don’t come into contact with any lateral forces. Site mounting positions to ensure that the gas springs cannot be fully compressed or ‘crushed’.

- If necessary, fit a mechanical stop to ensure that the gas springs cannot be over-extended or ‘stretched’.

Care and Maintenance

- Dictator gas springs are sealed for life and require no lubrication

- Never grip the piston rod with pliers or other similar tools. Damage caused to the piston rod will result in the premature failure of the gas spring.

- To achieve a long life gas springs should be operated no more than 6 times per minute and as a minimum once a month.

- Dictator gas springs with standard oils and seals will operate between -20 and +80 degrees. Avoid extreme heat or fire.

Sudden impacts and unseen forces can damage gas springs. This must always be avoided. Always follow safe disposal instructions.

Release Valves for Force Adjustment

Where a release valve is fitted, the force that the gas spring generates can be reduced. This is particularly useful for prototype and developmental work.

The co-axial valve comprises of a steel ball held against a machined seat by gas pressure within the cylinder. The valve is blanked off by a socket cap screw and ‘o’ ring seal.

Ensure that sufficient time is allowed to carry out the adjustment.It may be necessary to try the gas spring a number of times on the application before the optimum force is achieved.

The valve is concealed within the threaded end of the cylinder.

It will be necessary to remove any end fitting fitted to the cylinder before access can be gained to that valve. (Gas springs with integral; eyelets will have a small clearance hole through the eyelet allowing access to the valve.)

Force Adjustment Instructions

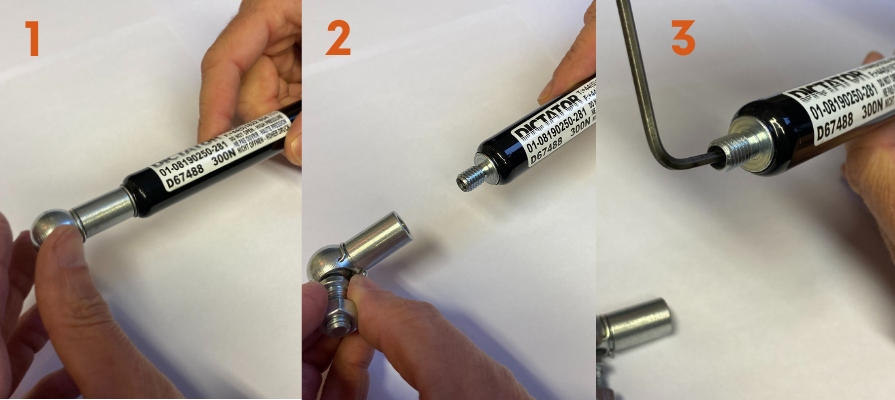

It may be necessary to remove the end fitting from the cylinder to access the valve.

If necessary, remove the end fitting by turning in an anti-clockwise direction – contact Dictator if in doubt, some end fittings cannot be removed. Do not use excessive force. Do not grip the cylinder with pliers or similar.

Using a 2mm hexagon key remove the socket cap screw by turning in an anti-clockwise direction.

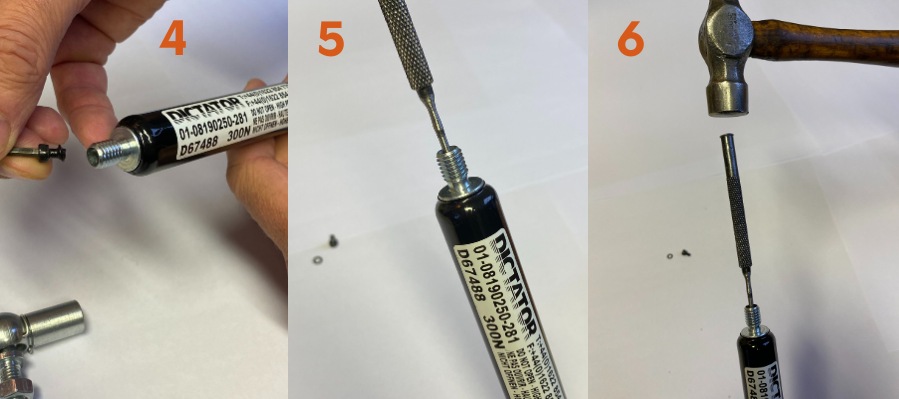

Ensure that the small rubber ‘o’ ring has come away from the valve with the socket cap screw, if not, remove from valve with small hook

Gently insert a 2mm parallel pin punch into the hole revealed by the socket cap screw. The punch will now be resting on the top surface of the ball.

Using a 200gm hammer, lightly tap the punch. Each time the punch is tapped, a small amount of gas is released from the cylinder. The more gas that is released, the greater the reduction in force

It may prove necessary to carry out step 6 a number of times to achieve the desired spring force. To avoid reducing the gas spring force too much, regularly try the gas spring on the application.

Take care not to strike the punch too hard – if the valve is damaged, all gas will be lost from the cylinder.

When the desired spring force has been achieved, replace the socket cap screw and ‘0′ ring, nip tight with hexagon key, do not over-tighten.

Should the gas spring force be reduced too much, DICTATOR can refill the gas spring for a small charge.